Mud Coolers

Mud Coolers

Deployed globally, OSSO's fleet of mud cooling systems are skid mounted, built in accordance to global standards and regulations and can be tailored to suit a range of operational requirements.

Drill with Confidence

OSSO's vast experience with geothermal wells and oil and gas HP/HT hole sections means that we truly understand the complexities and difficulties involved in launching such campaigns — while also possessing the know-how and proven field technology to successfully support them.

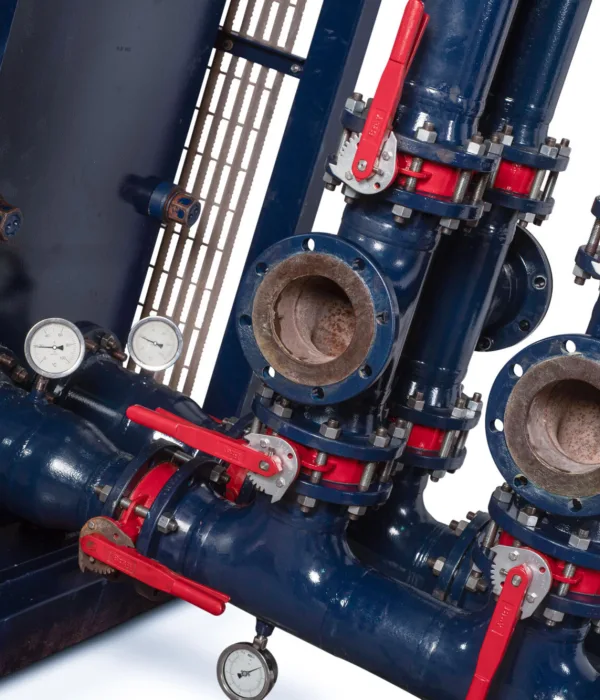

Our mud cooler rental packages come with complete piping assembly along with gauges to monitor both temperature and pressure. A duplex filter skid is provided to protect the mud cooler and remove any large solids from the feed, as well as a backflush manifold for cleaning the system.

They can be installed as an individual system or as a dual system, which can be set up in either parallel or series to maximise performance in high volume applications and high drilling fluid temperatures.

Our in-house modelling software ensures we propose the optimum solution based on individual well conditions including sections, circulating volumes, and mud rheology.

Our capabilities of handling high volumes of mud, being rated to 130°C and with a maximum surface more than 300m² within a single mud cooler means we have the premium solution to your HP/HT challenges.

Single or Dual

High Volume Mud Coolers

OSSO single and dual high volume mud coolers incorporate either one or two plate heat exchangers designed specifically for drilling mud and in accordance with PED/ASME codes and standards.

They have inlet/outlet pressure and temperature gauges, and the dual mud cooler can be operated as an individual unit, or in series.

The hot drilling mud from the mud surface pits is pumped to the mud inlet via a duplex strainer. The basket strainer prevents foreign objects entering the 4th generation design plate pack. A back flush arrangement within the mud cooler manifold is incorporated for flushing the plates in the plate pack.

Benefits

Specifically designed for water / oil-based muds with densities up to 19ppg (2.3sg) with solids content of 40%

Increases endurance in down hole measuring devices such as MWD — resulting in reduced round trip and decreasing actual drilling rig time

Increases life cycle elastomers in MWD, BOP, shaker screens, and pump liners

Assists in controlling mud rheology and mud flash point

Improves working environment within shaker house and active mud pit room