CASE STUDY

Reducing Environmental & Commercial Risk of TAR/Shutdown

Oil & Gas

CLIENT

UK Operator

LOCATION

Offshore North Sea

SERVICES

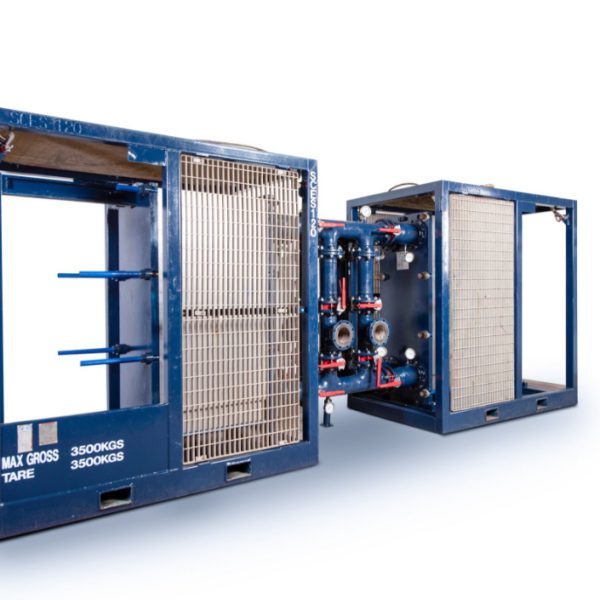

Mechanical separation

Fluid treatment

Sample analysis

THE CHALLENGE

A major North Sea operator required support with their waste/ullage management while running a platform shutdown. To avoid incurring extensive commercial and environmental costs for the fluid waste transportation back to shore they elected for a solutions that enabled the volumes of fluid to be treated at source.

HOW WE HELPED

OSSO was selected to facilitate the full clean down of the residual treated seawater which contained trace hydrocarbons. As part of the process all fluid waste was routed to a miscellaneous tank, where polishing, oil, water and solids separation occurred.

To ensure the levels were correct and within legal limits for overboard discharging, fluid analysis was carried out at a regular intervals through the duration of the project.

STRONG RESULTS

The fluids were separated and cleaned to <30ppm allowing for overboard discharge. In total 273m³ of volume was discharged, averaging close to 100% of the overall fluids processed. Not considering the logistical and personnel costs associated skip and ship, this process enabled an average cost saving of £600per/tonne for the Operator. By utilising the mechanical separation technique, OSSO further reduced wastage by removing the need for filters.

- Discharged 273m³ at source

- Supported the overall TAR plan/schedule

- Reduced resource constrains for the client

- Generated average cost saving of £600 per/tonne

- >95% processed fluids discharged at source

CONTACT OSSO

Got a question

about a project?

Related Case Studies

Geothermal drilling achieving a 25% temperature reduction

- 25% temperature reduction

- Full-service maintenance contract

- Annual equipment swap out and refurb programme

Improve drilling efficiencies in high temperature wells.

- Reduced days drilling NPT per section drilled

- 40% decrease in round trips per section drilled

- 95% reduction in tool DBR